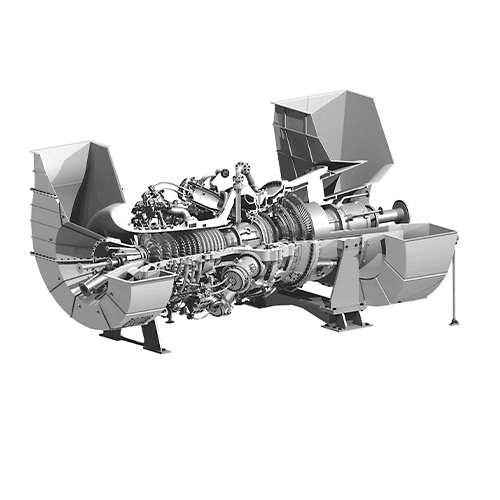

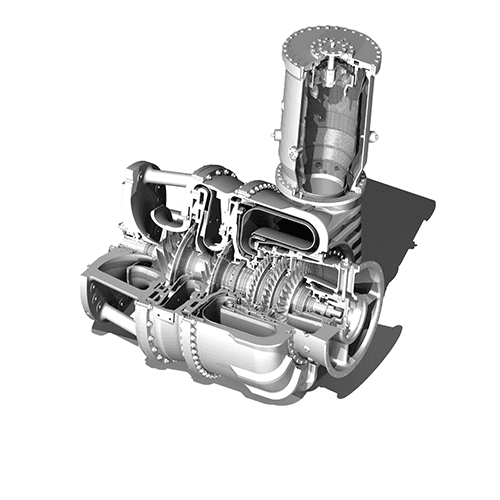

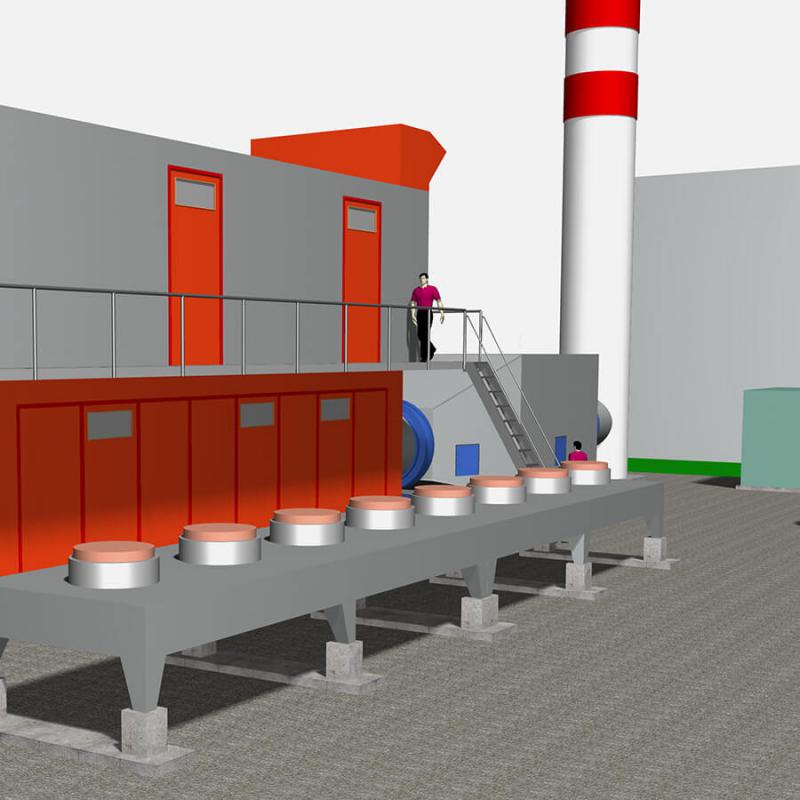

At the heart of the CHP systems are top-quality gas turbines manufactured by Japan's Kawasaki Heavy Industries. The gas turbines are installed in compact modules manufactured in plants in Germany and Poland in accordance with European norms and standards.

As a general contractor, we supply a turnkey complete cogeneration system based on Kawasaki turbines with a recovery boiler operating in modes including hot water or superheated steam production. The gas turbines are offered in five different power categories:

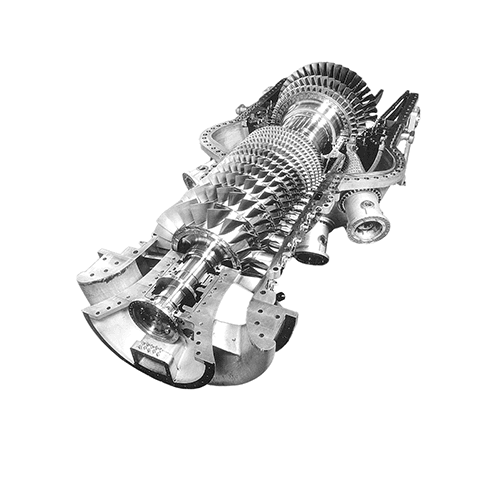

- GPB17D turbine-generator set with a capacity of approx. 1.7 MWe

- GPB50D turbine-generator set with a capacity of approx. 4.8 MWe

- GPB80D turbine-generator set with a capacity of approx. 7.8 MWe

- GPB180D turbine-generator set with a capacity of approx. 18.4 MWe

- GPB300D turbine-generator set with a capacity of approx. 30.1 MWe

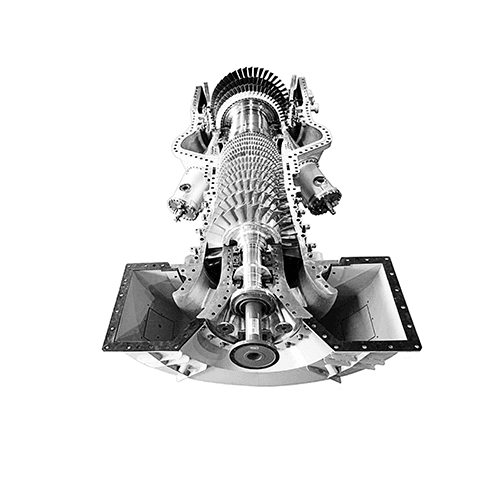

All of the Kawasaki gas turbines we offer can be adapted to run on 100% hydrogen fuel.

Kawasaki has implemented the use of hydrogen fuel in its 1.8 MWe Gas Turbine, which is the only industrial Gas Turbine running on 100% hydrogen. All Kawasaki turbines use the DLE (Dry Low Emission) technology to ensure low NOx emissions without the need for additional NOx reduction systems.

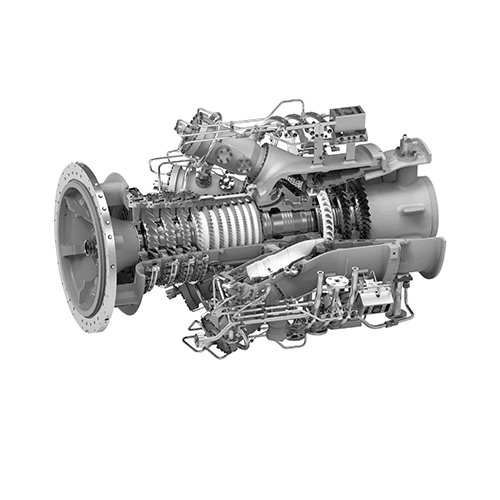

We perform our turnkey projects comprehensively, starting with the development of a concept together with the client, through to the execution of a complete multi-sector project including technology, construction and commissioning.

- Design work including basic, detailed and as-built designs in all disciplines

- Execution of construction and structural-mechanical works

- Assembly and installation work for technology and around technology installations,

- Installation of a gas supply system including a pressure reduction and measurement station as well as a gas compression system if required

- Installation of thermal power evacuation and its connection to the existing heat distribution system in the case of cooperation of the gas turbine unit with the hot water waste-heat boiler

- Installation of superheated steam evacuation and its connection to the existing Investor's system in the case of cooperation of the gas turbine unit with the steam waste-heat boiler

- Electrical works including the evacuation of MV and HV electrical power making a connection to the company network or to the voltage distribution transformer station,

- Automation and control systems including connection and integration with existing control and visualisation systems.

- Guaranteed measurements and commissioning.

- Comprehensive, long-term maintenance service of commissioned facilities.